In today’s competitive industrial landscape, achieving Manufacturing Business Growth requires more than incremental changes—it demands a comprehensive approach that integrates Lean Manufacturing Strategies with expert Business Growth Consultation. At our firm, we understand that driving Operational Efficiency and achieving Manufacturing Transformation go hand in hand with embracing modern methods and proven techniques. In this blog, we present a detailed roadmap for manufacturing companies eager to transform their production environment while adhering to the highest standards of quality and efficiency.

Driving Manufacturing Business Growth

Manufacturing companies face constant pressure to innovate and stay ahead. By focusing on Manufacturing Business Growth, we help companies identify key performance areas and create strategic plans that lead to significant expansion and profitability. Our approach centers around:

Evaluate current production processes.

Implementing best practices through Business Growth Consultation.

Leveraging Lean Manufacturing Strategies to reduce waste and streamline operations.

Enhancing Operational Efficiency by optimizing resource allocation and minimizing downtime.

Leading the charge towards Manufacturing Transformation for a sustainable future.

Embracing Lean Manufacturing Strategies

Implementing Lean Manufacturing Strategies is essential for businesses aiming to stay competitive. We utilize a suite of techniques that focus on eliminating waste, reducing costs, and improving quality. Our methodologies include:

Lean Process Improvement: Continuously refining processes to achieve better outcomes.

Manufacturing Efficiency Consulting: Offering expert advice on maximizing output with minimal resources.

Industrial Lean Management: Adopting management practices that drive productivity and streamline operations.

Cost Reduction Strategies: Identifying and implementing measures that lower production expenses without compromising quality.

Production Optimization: Enhancing production workflows to deliver products faster and more efficiently.

These strategies are designed to foster a culture of continuous improvement, ensuring that every aspect of your manufacturing operation is aligned with modern industry standards.

Don't Just Read About Success,

Take the Next Step

Let's Schedule a Consultation Meeting

A Step-by-Step Transformation Roadmap

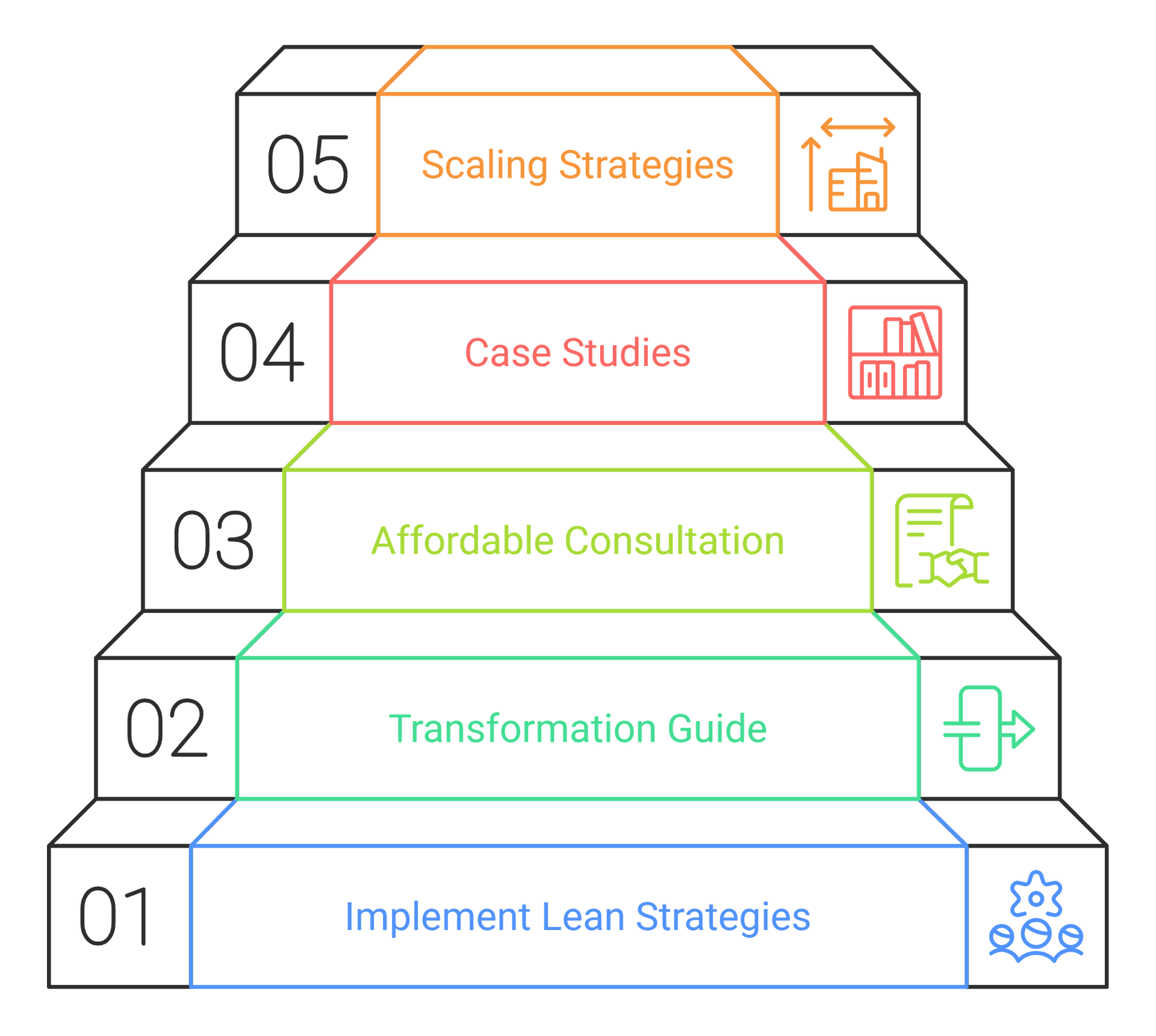

For companies looking to evolve, our comprehensive guide provides actionable steps. Here’s how we address transformation:

How to implement lean strategies in manufacturing for growth

We work closely with your team to understand your unique challenges and craft a customized plan that integrates lean principles into every layer of your operation.Step-by-step guide to manufacturing business transformation

Our structured approach offers clear stages from initial assessment to full-scale implementation ensuring that each step builds on the success of the previous one.Affordable manufacturing growth consultation services

We deliver cost-effective solutions that offer a high return on investment, making our expert guidance accessible without straining your budget.Case studies on lean manufacturing process improvement

Our proven track record is backed by real-world examples of companies dramatically improving their processes and reaping substantial benefits.Strategies for scaling manufacturing operations using lean principles

We help you develop scalable solutions that grow with your business, ensuring long-term sustainability and competitive advantage.

Action-Oriented Steps to Success

Taking immediate action is crucial for long-term success. Our approach is designed to:

Boost your manufacturing growth by identifying and capitalizing on untapped opportunities.

Transform your production today with quick wins and sustainable improvements.

Optimize operations now through data-driven analysis and lean process reengineering.

Improve efficiency instantly by streamlining workflows and eliminating bottlenecks.

Get a lean consultation to begin your journey towards a more agile and responsive manufacturing environment.

These action-oriented steps are not just theoretical, they are practical measures designed to create measurable improvements in your production line.

Trending Insights in Modern Manufacturing

Staying abreast of industry developments is essential. We continuously monitor:

Top trends in lean manufacturing 2025 to ensure our methods are current and effective.

Emerging lean strategies that offer new ways to solve traditional challenges.

Modern manufacturing consulting techniques that blend technology with human expertise.

Innovative business growth techniques that drive operational success.

Future of lean manufacturing and how it will shape the next generation of industrial practices.

By integrating these trending keywords into our strategy, we ensure that your business remains at the forefront of innovation and efficiency.

Sustainable Growth Through Lean Manufacturing

Unlocking your manufacturing business's true potential is within reach. With Business Growth Consultation that leverages Lean Manufacturing Strategies, you can achieve remarkable Manufacturing Business Growth while significantly enhancing Operational Efficiency and driving Manufacturing Transformation. Our comprehensive approach—incorporating Lean Process Improvement, Manufacturing Efficiency Consulting, Industrial Lean Management, Cost Reduction Strategies, and Production Optimization—provides you with a step-by-step guide to manufacturing business transformation that is both affordable and effective.

Take action today to Boost your manufacturing growth, Transform your production, Optimize operations, Improve efficiency instantly, and Get lean consultation now. Embrace the Top trends in lean manufacturing in 2025, explore Emerging lean strategies, and prepare for the Future of lean manufacturing with our expert guidance. Your journey towards modern manufacturing excellence begins here.

Don't Wait for the Right Time,

Let's Talk & Implement it

Let's Schedule a Consultation Meeting

Expert Q&A on Lean Strategies

What is Business Growth Consultation, and how does it apply to manufacturing?

Business Growth Consultation involves expert guidance on optimizing operations, increasing efficiency, and scaling production. For manufacturing, it focuses on improving Operational Efficiency, reducing waste, and streamlining processes through Lean Manufacturing Strategies.

Business Growth Consultation involves expert guidance on optimizing operations, increasing efficiency, and scaling production. For manufacturing, it focuses on improving Operational Efficiency, reducing waste, and streamlining processes through Lean Manufacturing Strategies.

How do Lean Manufacturing Strategies drive growth in the manufacturing sector?

By implementing Lean manufacturing strategies, businesses can eliminate inefficiencies, reduce costs, and improve production speed. Techniques such as Lean Process Improvement and Industrial Lean Management help manufacturers stay competitive while maximizing output.

By implementing Lean manufacturing strategies, businesses can eliminate inefficiencies, reduce costs, and improve production speed. Techniques such as Lean Process Improvement and Industrial Lean Management help manufacturers stay competitive while maximizing output.

How can Manufacturing Efficiency Consulting improve operational performance?

Consulting experts analyze existing processes, identify bottlenecks, and implement Lean Process Improvement techniques. These insights help businesses reduce downtime, enhance resource utilization, and increase overall efficiency.

Consulting experts analyze existing processes, identify bottlenecks, and implement Lean Process Improvement techniques. These insights help businesses reduce downtime, enhance resource utilization, and increase overall efficiency.

How can Manufacturing Efficiency Consulting improve operational performance?

Conduct a detailed Business Growth Consultation.

Identify wasteful processes and areas for improvement.

Implement Cost Reduction Strategies without compromising quality.

Optimize workflows for Production Optimization.

Monitor progress and continuously refine processes.

Conduct a detailed Business Growth Consultation.

Identify wasteful processes and areas for improvement.

Implement Cost Reduction Strategies without compromising quality.

Optimize workflows for Production Optimization.

Monitor progress and continuously refine processes.