In today's competitive manufacturing environment, a Manufacturing Efficiency Boost is essential for staying ahead. To achieve this, companies need to embrace a comprehensive approach that focuses on Lean Manufacturing Optimization, integrates Six Sigma in Manufacturing, and leverages Kaizen in Manufacturing. This blog serves as a Comprehensive guide to implementing kaizen for manufacturing efficiency and provides actionable insights on how to implement lean manufacturing strategies for operational excellence while driving Lean Manufacturing Efficiency throughout your operations.

Introduction

Manufacturers constantly seek ways to eliminate waste and improve productivity. With the rise of digital tools and advanced methodologies, now is the perfect time to transform your operations. Our blueprint outlines a proven method to transform your manufacturing efficiency now, ensuring that you stay competitive in a rapidly evolving market.

Understanding Operation Optimization

Operation Optimization is at the heart of manufacturing success. It involves the strategic use of proven methodologies such as Lean, Six Sigma, and Kaizen to eliminate waste and enhance efficiency. Here’s how these concepts work together:

Lean Manufacturing Optimization focuses on streamlining processes to remove non-value-added activities.

Six Sigma in Manufacturing uses data-driven techniques to reduce defects and improve quality.

Kaizen in Manufacturing is about Continuous Improvement with Kaizen—implementing small, incremental changes that add up to significant gains.

Together, these approaches form a powerful Manufacturing Sales & Growth Blueprint for operational excellence.

Are you Ready to Transform Your Manufacturing Efficiency?

Our Data-Driven Operation Optimization Strategy

We develop and implement a data-driven operation optimization strategy tailored to your business. This strategy is built around several key components:

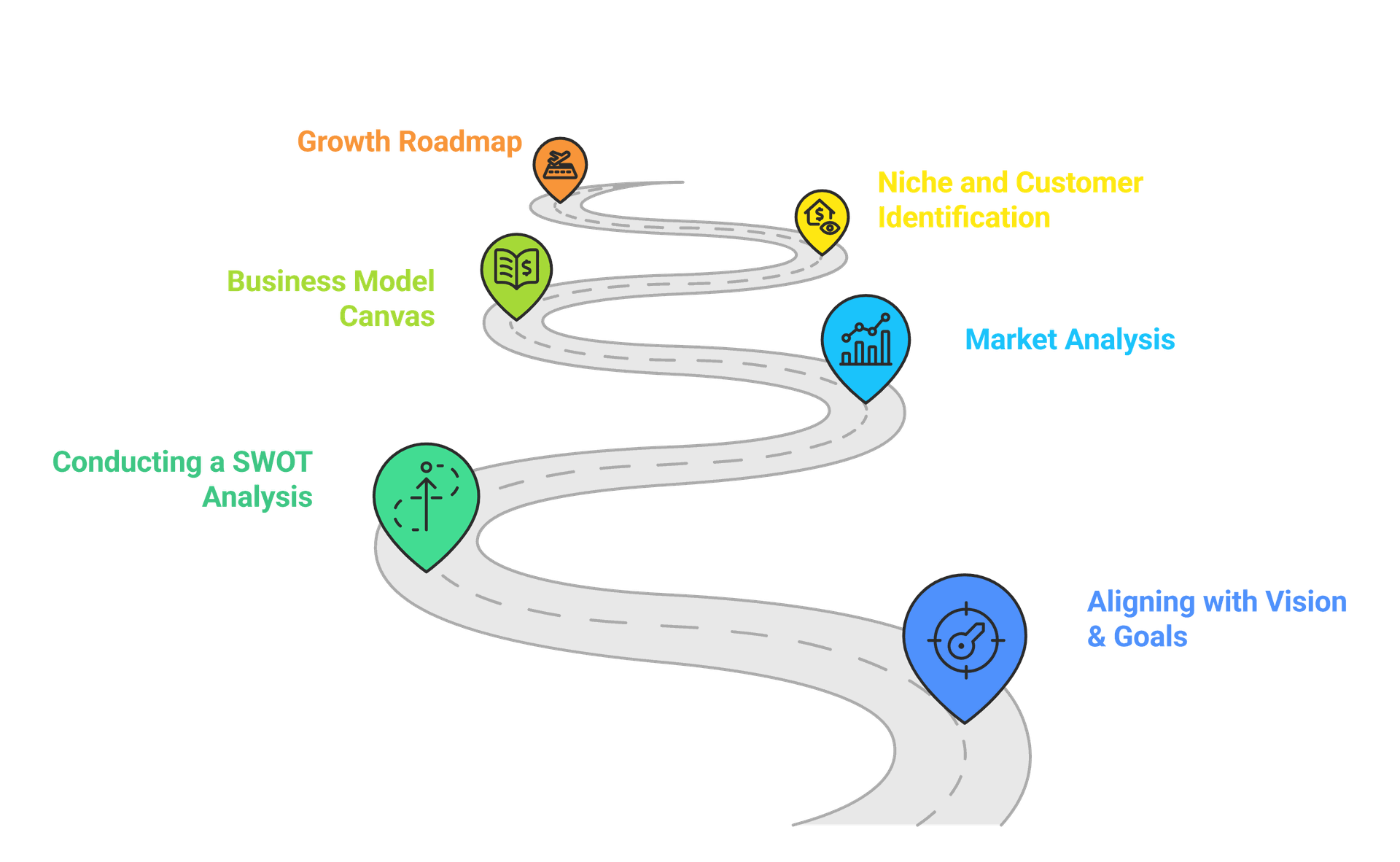

1. Aligning with Your Vision & Business Goals

Strategic Alignment: Ensuring that the sales strategy is in harmony with your company's overarching vision and objectives. This alignment guarantees that all initiatives contribute directly to achieving a Manufacturing Efficiency Boost.

2. Conducting a SWOT Analysis

Strengths and Weaknesses: Evaluate internal factors to identify what your company excels at and areas needing improvement.

Opportunities and Threats: Analyze external factors such as market trends and competitor activities.

Strategic Planning: Utilize SWOT insights to inform decisions, ensuring that your strategy leverages strengths, addresses weaknesses, capitalizes on opportunities, and mitigates threats.

3. Market Analysis

Competitive Landscape: Conduct thorough research to understand industry dynamics.

Customer Segmentation: Identify distinct customer groups to tailor your approach.

Trend Analysis: Monitor market trends, including Kaizen Implementation Trends and Latest Process Optimization Techniques, to keep your strategy up-to-date.

4. Business Model Canvas

Key Activities and Resources: Define the essential actions and assets required to deliver value.

Value Proposition: Clarify the unique value your products or services offer.

Revenue Streams & Cost Structure: Identify and optimize income sources while managing costs efficiently.

Customer Relationships and Channels: Establish effective methods for reaching and engaging customers.

Partners and Stakeholders: Recognize key partners who contribute to your business model.

5. Niche and Customer Identification

Target Audience & Brand Positioning: Pinpoint specific market segments that align with your offerings and craft a compelling brand message.

Needs Assessment & Solution Mapping: Understand customer pain points to tailor your products or services effectively.

6. Growth Roadmap

SMART Goals: Set Specific, Measurable, Achievable, Relevant, and Time-bound objectives.

Key Performance Indicators (KPIs): Define metrics to monitor progress.

Marketing and Sales Strategy Execution: Implement focused campaigns and sales tactics designed to achieve your goals.

Kaizen means change for the better. It is not a one-time event but a continuous journey of improvement.

Benefits of Our Operation Optimization Strategy

Adopting our comprehensive strategy offers numerous benefits:

Predictable and Scalable Revenue: Structured plans lead to consistent income and facilitate business expansion.

Improved Lead Quality and Conversion Rates: Targeted efforts attract prospects that are more likely to convert, enhancing ROI.

Enhanced Brand Positioning: A clear understanding of the market and customer needs differentiates your brand from competitors.

Operational Efficiency: Streamlined processes reduce costs and improve overall productivity.

Informed Decision-Making: Data-driven insights enable proactive adjustments to strategies, keeping your business agile and responsive.